When you need to add permanent text, graphics, or branding

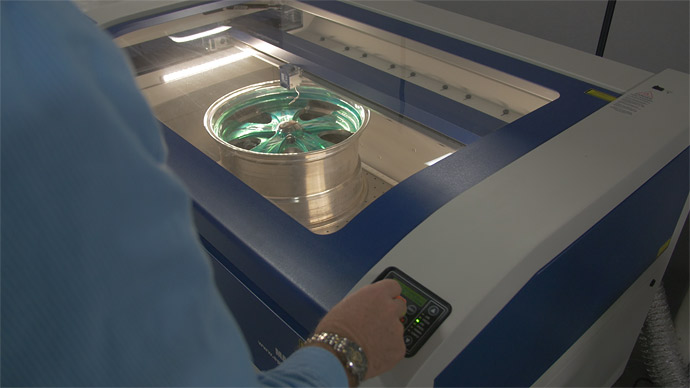

Mile High Powder Coating is proud to announce the addition of a CO2 laser for marking and engraving to our roster of finishing services. Mile High can now mark or engrave coated metals, aluminum, glass, plastics, and more.

Laser marking and engraving is rapidly supplanting silk screening as a marking technology for certain surfaces due to its permanence, cost-effectiveness, and the ability to create sequential output (serial numbers, etc.). It is a computer-driven, non-contact process with superior quality, resolution, accuracy, and design flexibility.

Our cutting-edge CO2 laser allows us to do everything from industrial part and asset marking to custom marking and engraving work (rims, valve covers, dash box covers, glass emblems and promotional items). Our laser system offers a generous 40” X 28” engraving area. Whether your project is a one-of-a-kind design prototype or you need high volume part marking or serialization, precision computer control means the last part marked will look as good as the first!

Our laser system was originally purchased for adding branding and/or graphics to powder-coated surfaces (logos or text on powder coated products and graphic designs on powder coated rims) but has far greater versatility. We can mark or engrave powder coated metal, aluminum, wood, glass, plastic, and more. Check our specs section below for a full list of our capabilities.

We can apply logos, graphic designs, barcodes, text or serial numbers. For graphics, the quality of the source image is really important; the higher the image quality, the better your engraving. For graphic sources, we can use scanned photos, logos, bitmaps, other images, text, and even AutoCAD and other vector-type files. If we can print it, we can mark or engrave it for you. Check our specs section below for a full list of files supported graphic files.

Laser Marking and Engraving Applications

Industrial/Manufacturing

- Design prototype marking

- Product laser marking

- Serialization of parts

- Sports equipment

- Outdoor equipment

- Tools

Commercial

- Auto part decoration and branding

- Custom signs

- Asset or tool marking

- Name Plates

- Promotional Items

- Company identification tags

Individual

- Automotive Rims

- Asset or tool marking for identification / traceability

- Photographs on metal

- Automotive Glass emblems

- Automotive Glove Box Covers