Environmental Simulation Testing

Repair • Restore • Refinish • Renew

How well is your product’s powder coat finish able to withstand corrosion over time? Extreme temperature, humidity or freeze-thaw cycles? Because rust never sleeps …

At Mile High Powder Coating, we have taken our Quality Assurance capabilities to the next level by investing in dedicated environmental simulation and analysis equipment. These specialized testing chambers allow us to simulate the adverse environmental conditions a product may be exposed to but at an accelerated rate.

We can ensure the long term durability and reliability of your product’s powder coat finish by subjecting your parts or test coupon to salt-spray and thermal testing on request. These tests check corrosion resistance and resistance to freeze thaw cycles for coatings respectively. Here are the specific accelerated simulation analyses we can perform in-house:

- salt spray testing to ASTM B117

- resistance to humidity to ASTM D2247-68

- freeze/thaw thermal cycling to ASTM D6944-09e1 or MIL-STD-810D

Benefits Of Environmental Testing

We don’t see environmental simulation testing as an additional expense, rather it is a proactive investment that reduces the risk of product failure and ultimately saves you time and money by allowing you to:

- Reduce product development time during prototyping

- Identify potential coating issues prior to production runs

- Ensure product quality and reliability

- Forecast product life expectancy

- Anticipate product failures

- Reduce warranty service and costs, and

- Protect your reputation – and ours!

Mile High Powder Coating is committed to excellence in powder coating and testing services while taking you to a new level of confidence and trust.

Economies And Efficiencies

Testing is completed in-house – in just a few days. We provide these services at a nominal rate – at significantly lower cost than traditional testing laboratories. By getting your environmental simulation testing done at Mile High along with your powder coating, you can get your test results in a fraction of the time and at a fraction of the usual cost of traditional testing laboratories.

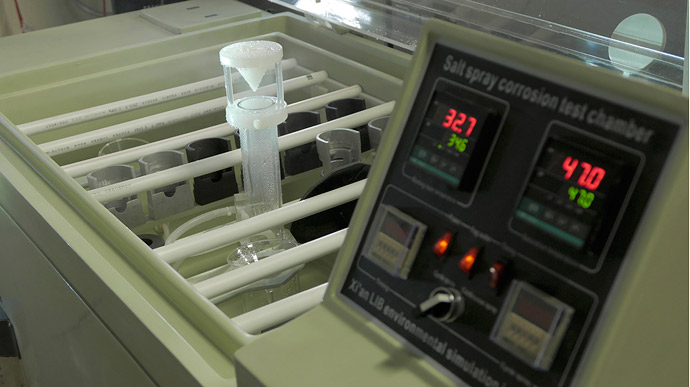

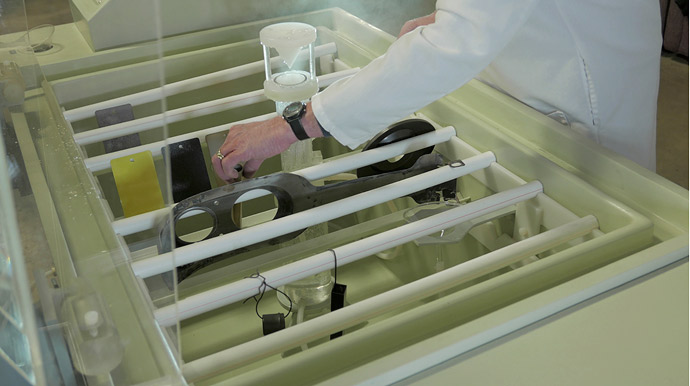

Corrosion Testing: Salt Fog / Salt Spray Testing Capabilities

How well is your finished product able to withstand corrosion over time? Corrosion occurs as a result of metal exposure to chemicals or moisture; salt accelerates this process. The chamber reproduces the damage caused by rain, dew, and salt water by exposing your part or coupon to accelerated corrosive saline fog. We follow ASTM B117 for corrosion testing; this test is widely recognized and has been approved for use by Department of Defense agencies.

How well is your finished product able to withstand corrosion over time? Corrosion occurs as a result of metal exposure to chemicals or moisture; salt accelerates this process. The chamber reproduces the damage caused by rain, dew, and salt water by exposing your part or coupon to accelerated corrosive saline fog. We follow ASTM B117 for corrosion testing; this test is widely recognized and has been approved for use by Department of Defense agencies.

Corrosion Testing Chamber

Our salt fog / salt spray corrosion chamber temperature range is ambient to 140F degrees with a humidity range of 95%-98% RH.

Capacity: 3’ x 4’ x 22”

Our Test Chamber is built to ASTM B117 specifications. A final test analysis report is provided.

Climatic Testing: Temperature And Humidity Testing Capabilities

How well does your finished product stand up to temperature and humidity over time? We can simulate the temperature/humidity extremes your product may be exposed to but at an accelerated rate.

How well does your finished product stand up to temperature and humidity over time? We can simulate the temperature/humidity extremes your product may be exposed to but at an accelerated rate.

Freeze/Thaw/Humidity Thermal Cycling Chamber

The chamber provides low/high temperature environmental cycle testing with the addition of varying humidity. Our environmental chamber has a programmable temperature range from -31F to +395F degrees and the ability to generate 20% to 98% relative humidity (RH).

Capacity: 8 cubic feet.

We can perform testing to ASTM D6944-09e1, MIL-STD-810D, or to customer supplied criteria. Samples can be run with or without scribing (cutting to expose the surface below). Failures are rated 0 – 10 in accordance with ASTM 1654.92.

A final test analysis report is provided.

The addition of comprehensive environmental simulation testing capabilities is one more step Mile High Powder Coating has taken to ensure our customers receive the very best corrosion resistance and powder coat durability. When quality counts, you can count on Mile High Powder Coating to take you to the next level.

Contact us to learn more about our powder coating services and environmental simulation testing capabilities.