Capabilities & Quality

Large Capacity

Large can mean two things either the ability to run lots of parts or the ability to handle parts that are large in size. At Mile High Powder Coating we can do both.

Semi-Automated Line System

We have a large digitally controlled semi-automated powder coating line which washes, dries, powder coats and bakes the coating with all of this happening while the parts are moving on an overhead conveyor. The system can handle as many as 101,000 parts on a single shift alone. We use operators instead of robots to apply the powder as we have found nothing is a substitute for the human eye.

One of the largest curing ovens in Colorado

We have one of the largest ovens in Colorado measuring 6’ wide x 9’ tall and 25’ long giving us excellent capacity to cure large parts that others cannot begin to handle. This oven also has an overhead rail system which allows the parts to be moved efficiently and will no danger to damage of the part or coating

Quality through Preparation and Application

Quality is what Mile High Powder Coating is all about and has been since day one. We don’t take shortcuts when it comes to making the end product as good as humanly possible. Powder is powder. We all use the same suppliers so it comes down to two very import steps: preparation and application.

Intensive Pre-treatment and Surface Preparation

We spend an incredible amount of time in prepping the parts for coating. We strip the part to bare metal either thermally (burn-off oven) or chemical for aluminum products. We then micro etch/clean the surface using Phosphate which is applied using high pressure and temperature. At this point the parts are clean and some cases (clear coats) we handle the parts with lint free gloves to protect the surface from contamination and finger prints.

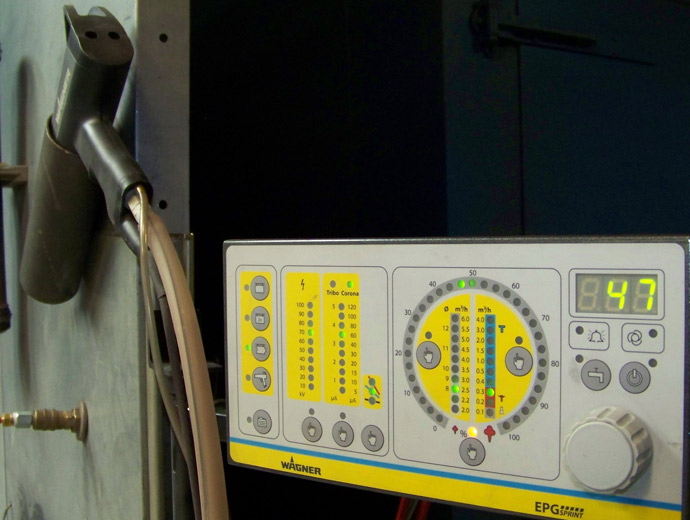

Expert Powder Coat Application

The parts are then hung to minimize hook marks and then the powder is applied using the latest generation powder guns.

Mile High Powder Coating has very experienced powder coaters with many of our employees having 10+ years in the business. Experience counts in powder coating more than any other painting and we have the best crew to do the job right the first time.

Digitally Controlled Ovens, Stringent Testing

Now the parts are cured in a digitally controlled oven and even the time in the oven is digitally controlled.

The parts are removed from the oven and allowed to cool. Once cool the powder coating is as tough as it ever will be. We then QC the parts by measuring the coating is at the proper thickness which is 3-5 mils. We always shoot to the higher side.

We also periodically test parts by performing a cross hatch test. This test confirms proper powder coating adhesion. No adhesion, no longevity of the coating.

Once the parts pass our quality inspection process they are packaged and stored until being picked up.

We have our process equipment and chemicals periodically checked by outside quality sources to validate that our entire processes meet the highest industry standards.

A Better-Than-Factory Finish

Factory finishes for the most part are all about throughput more than perfection.

Our finishes are all hand applied with more coating thickness than factories apply, and each and every part is inspected to insure total customer satisfaction. No factory can do this.

Denver’s Clear Powder Coat Specialists

Applying clear coats is more technical art than anything else. We have a dedicated clear coat oven that is “Ultra Pure” from contamination.

We have a tremendously experienced powder coater that has this artistic ability to give outstanding clear coat results. He is extremely talented and we’re lucky to have him. I can’t tell you how many jobs have been brought to us over the years because we are very trusted in applying clear coats. We even offer several different gloss sheens more than anyone else; to give you that look you’re looking for.

In-house Stripping Capabilities

Sandblasting

Mile High Powder Coating has the ability to sandblast just about everything that would fit in one of our 5 powder coating ovens.

Chemical Stripping

We offer chemical stripping for non-ferrous materials such as aluminum, brass, or tin or parts where sand blasting would be too harsh to the surface. The chemical removes any paint that is on the surface while leaving the parent surface untouched. This is most beneficial for polished surfaces such as faucets as an example.

Thermal Stripping

We also use burn-off ovens to strip metal surfaces when needed. Heat breaks down paint, oil, and plastic on metal parts and turns them to ash that can be rinsed or sand-blasted away.

Pick up and Delivery

For a nominal charge we can pick up and deliver back to you your project once it has been powder coated. We are all about service here at Mile High Powder Coating. Please see the FAQ on the Powder Coating Services page for pricing.